Less emissions

Reduction of atmospheric CO2 emissions.

Producing raw materials to make reusable asphalts

Pavement recycling

Thanks to the use of bitumens and emulsions containing rejuvenators, which we produce in our plants, we can recycle and reuse highway pavement that has become deteriorated by use and weather. In this way, we are able to reduce the quantity of asphalt waste that ends up in landfills by giving it several more lives.

Additionally, we are developing our own technology that will give roads "self healing" capabilities when its materials begin to show signs of damage, therefore increasing its useful life.

We are also working on initiatives with other industrial sectors (industrial symbiosis) like tire manufacturers. Through our own development techniques, we collaborate with these industries in evaluating and reusing its waste to produce asphalts, even improving the properties of conventional asphalts.

Circular benefits

Less emissions

Reduction of atmospheric CO2 emissions.

Waste reduction

In accordance with the European Commission and the Government of Spain.

Less fresh water use

Reduce our water footprint.

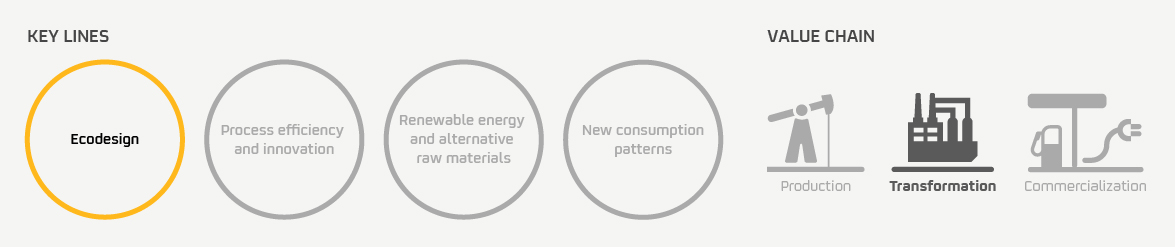

Classification by key lines and value chain

Our circular economy projects are aligned with the key lines of our strategy and are present throughout our entire value chain, from obtaining raw materials to commercializing products and services.

Find out more about our circular economy projects

4Refinery

We implement solutions to transform biomass into advanced biofuels with low CO2 emissions.

Find out more