High-quality lubricants made from regenerated bases

On the path to meeting our goal

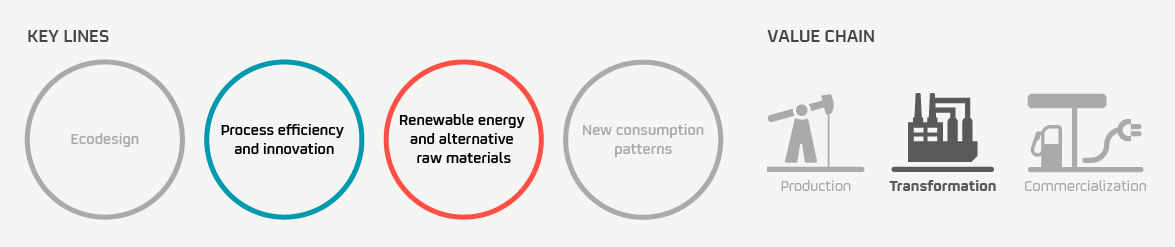

By incorporating regenerated raw materials into the manufacturing of new lubricants, we can decrease the amount of virgin feedstock we use that's derived from fossil sources and extend the useful life of used oils.

In this way, we are able to commercialize products that contribute to lowering our carbon footprint, and at the same time, strengthen our commitment to sustainability and to our customers, who increasingly demand more sustainable products.

Thanks to innovation, we can manufacture more efficient, environmentally-friendly products, which brings us closer to meeting our ambition of becoming a net zero emissions company by 2050.

Circular benefits

The resulting product, in addition to complying with stringent quality control standards, provides the following benefits:

Waste conversion

It regenerates waste by transforming it into raw materials.

Support for circular economy

According to the guidelines established by the European Commission and the Government of Spain.