Eco-aggregates: A new product for capturing CO2

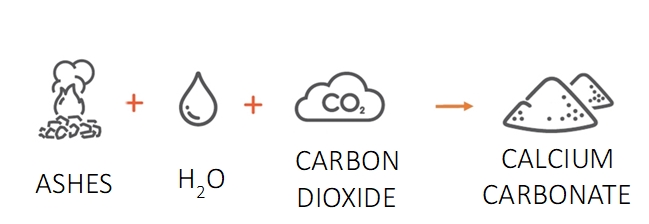

What is the CO2 mineralization project?

At Repsol, together with our partner O.C.O Technology Limited, we’re going to start building a plant in the vicinity of our Petronor facilities to incorporate O.C.O technology for the manufacture of aggregates (gravel) produced from CO2 captured at the Petronor refinery and ashes. Aggregates are the raw material used by the construction industry to manufacture concrete and roads, among other uses.

These eco-aggregates promote the reuse of waste such as ashes by converting them into new raw materials that we reintroduce back into production cycles. The use of eco-aggregates will help reduce the consumption of natural aggregates.

Our figures

22,000

tonnes/year

of ashes from the incineration of MSW that will be reused

56,000

tonnes/year

of eco-aggregates produced

2,200

tonnes/year

of CO2 captured and reused

16

times

the carbon footprint is reduced compared to other traditional products