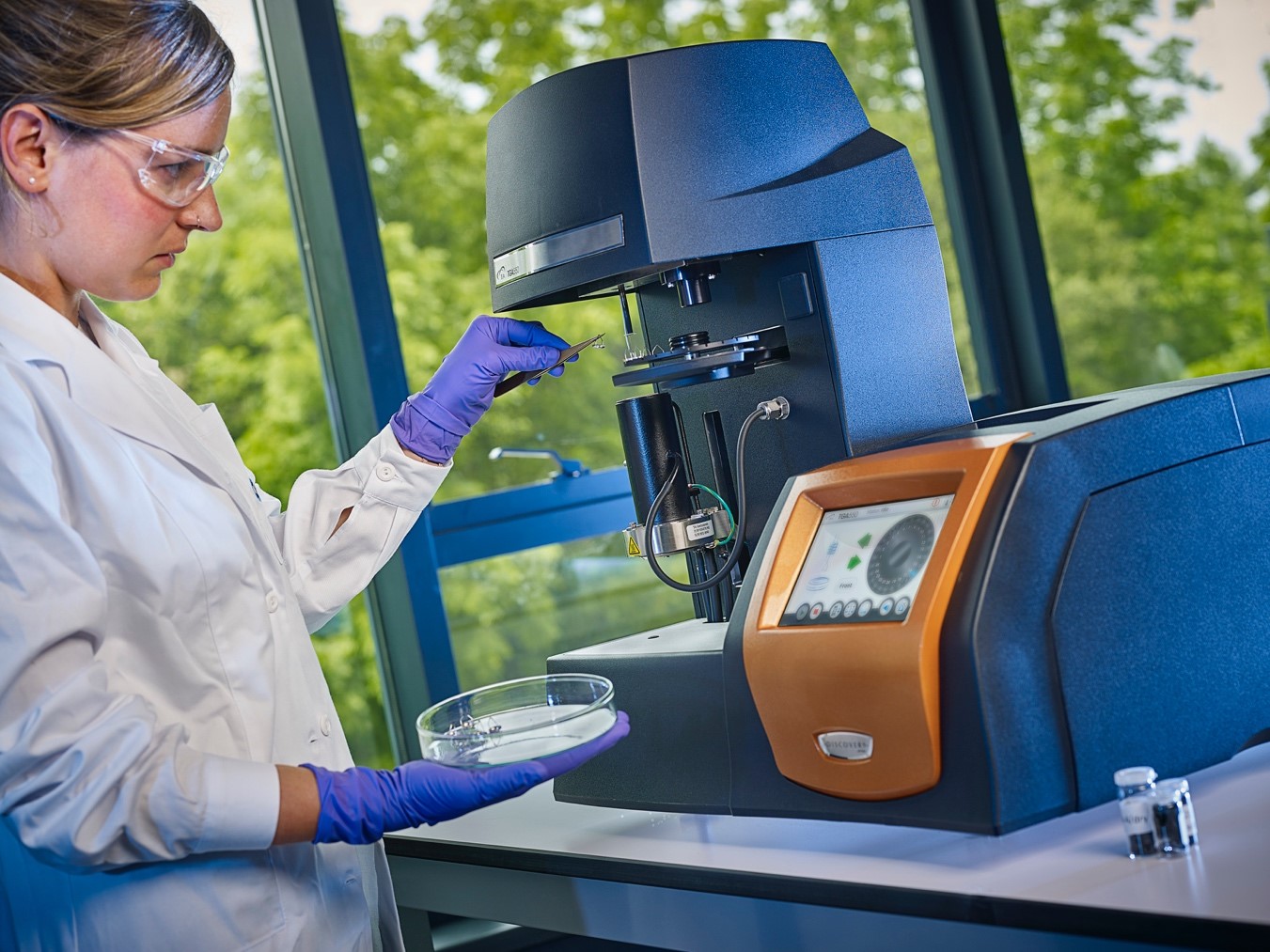

We're working towards the future at the Repsol Technology Lab

Innovation and quality applied to Repsol’s Chemicals Division

Today’s challenge: Building a sustainable future with better products and differentiated services.

Shaping the future of chemicals

More than 250 scientists and researchers

In a space with a total surface area of over 50,000 m2

One of the most important in Europe