Types of reverse logistics

Taking into account the process or treatment given to the product that is returned to the manufacturer or distributor, we can classify reverse logistics into two types:

Reverse logistics

A key part of the circular economy

Reading time: 9 min

Have you ever had a drink that came a glass bottle in a restaurant? Or bought a product online? These two actions have more in common than you think, and it's because they're possible thanks to reverse logistics.

When we drink a soda in a glass bottle at a restaurant, the bottle returns to its point of origin to be reused for a new drink. And when we want to return a product that we purchased online, we have this same option by following the distributor's instructions. In other words, both cases have in common that a selective collection channel has been enabled.

What is reverse logistics?

Reverse logistics or reverse distribution is a stage in the supply chain in which the product is returned from the point of sale to the manufacturer or distributor for recovery, repair, recycling, or disposal.

If in conventional logistics the product is moved from point A to point B, in reverse logistics, it's returned from point B to point A. This way, each company establishes a channel for waste recovery (industrial, electronic, construction, etc.), depending on the type of activity it carries out and its needs. Therefore, reverse logistics is part of a company's value chain, as it's an additional link that's added to optimize the production process and customer loyalty.

In addition, reverse logistics is related to the circular economy because its main goal is to recycle or reuse products and materials to extend their life cycle as much as possible. And, consequently, decrease the use of the planet's natural resources.

So, what's the main objective of reverse logistics?

The main objective of reverse logistics is to manage the flow of products, materials and resources from the final consumer to the origin of the supply chain in order to maximize their value and minimize their environmental impact.

What are the 3Rs of reverse logistics?

These three practices together make up the 3Rs of reverse logistics and are essential for sustainability and efficiency in supply chain management.

Types of reverse logistics

Taking into account the process or treatment given to the product that is returned to the manufacturer or distributor, we can classify reverse logistics into two types:

Green reverse logistics

Products returning from the point of sale to the source go through a process of repair, recycling, or disposal in an environmentally friendly way before being stored or sold again. For example, at Repsol, we reuse the packaging in which some products are sold.

Reverse return logistics

In this case, the product that returns to the point of origin is put back into stock to be sold again without needing to go through any additional processes. For example, this could involve an item of clothing that has been returned to a store.

Benefits of reverse logistics

Because of its multiple benefits, many sectors are committed to this strategy aimed at extending the life cycle of products and processes:

Caring for the environment

Reverse logistics allows us to reduce the waste we generate, which minimizes the environmental impact. The material returned to the point of origin is part of a recycling or reuse chain.

Stock control

Return operations involve considerable effort for companies, so there's greater control over resources and products, especially inventory.

Better customer service

Companies' high level of management and response capacity leads to a better assessment by the customer. In addition, reverse logistics provides valuable information for the manufacturer or distributor. It makes it possible to evaluate the reasons for the return, aspects that can be improved, control products that have arrived in poor condition, etc.

Cost reduction

The manufacturer can reuse the packaging or even manufacture new material from it and save costs on purchasing raw materials. By significantly reducing the number of packages, the cost of manufacturing the product is also reduced.

In short, when there is greater control over the product, more efficient action is taken at all process stages. This translates into better service for society, less environmental impact, and greater profitability for companies.

Current examples of reverse logistics

Reverse logistics is a crucial process in supply chain management that involves recovering products and materials after their use or distribution. This practice focuses on several key areas:

Repsol and reverse logistics

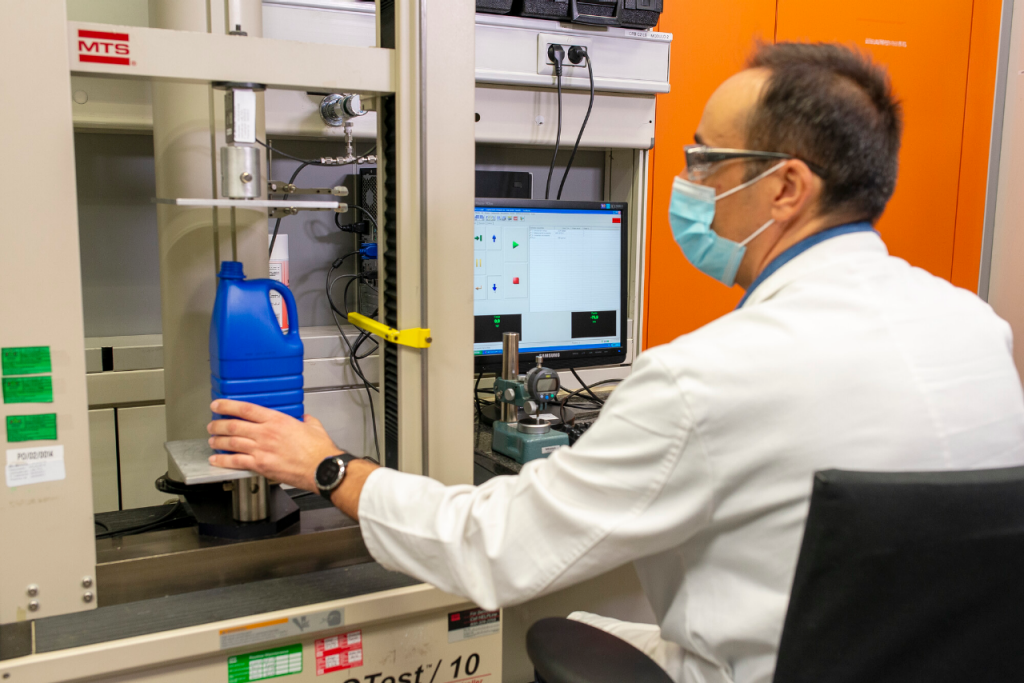

At Repsol, we manage resources efficiently to strengthen our value chain in which we prioritize the satisfaction of our customers and employees and the positive impact on society and the environment.

Therefore, some of the actions we have taken are the implementation of a reverse logistics system in which we optimize the useful life of the containers in which the products are marketed and contribute to the development of clean technologies with non-labelable oils. We also work with environmentally committed suppliers and purchase pellets from responsibly managed forests.

In addition, following our commitment to sustainability, we have the Circular Economy Business Strategy Certification granted by AENOR (Spanish Association for Standardization and Certification) in which waste management plays a key role. As stated by Ismael Pereda, Sr. Manager at Repsol, "The goal is to recover 100% of waste, providing circular solutions throughout the value chain."