Asphalt bitumens

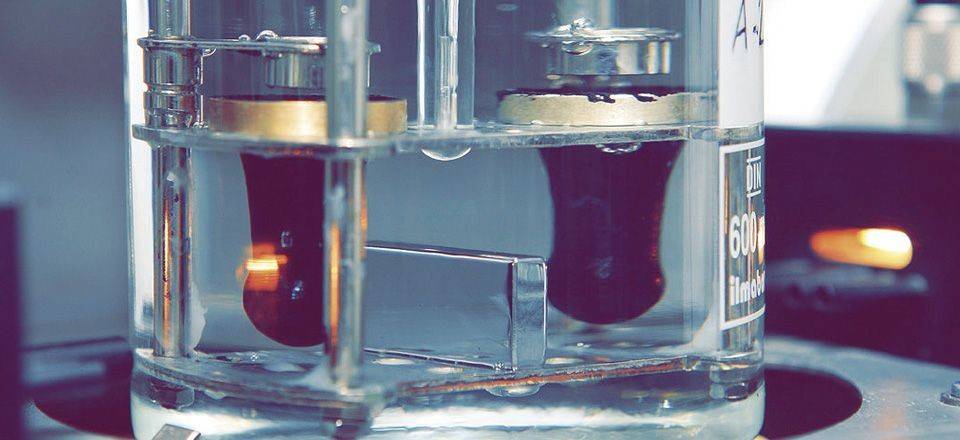

Asphalt bitumens are binders from the distillation of crude oil. They are characterized by their viscoelastic performance which depends on temperature and their high chemical stability. They are also called penetration bitumens due to the fact that this property is used to classify them.

Uses and characteristics

Bitumen is the component that binds and gives cohesion to bituminous mixtures and is mainly responsible for the properties of bituminous mixtures. Its consistency can be modified by applying a higher or lower temperature, which allows for easy handling, aggregate wrapping, compaction of the mixes and adequate behaviour at service temperatures. Asphalt bitumens have two main areas of application: roads and industrial environments.

Roads

- Conventional hot bituminous mixtures

- Polymer-modified bitumens

- Crumb rubber-modified bitumens

- Fuel-resistant bitumens

- Multigrade bitumens

- Emulsions (conventional and modified)

Industrial applications

- Emulsions and mastics for industrial waterproofing and paving

- Asphalt sheets

- Pipe coating

- Hydraulic works

- Sealing of joints

- Asphalt paints, etc.

The most commonly used conventional bitumens in Spain are those with a penetration of 35/50 and 50/70, which are used to manufacture conventional bituminous mixes. This is mainly due to climatic reasons as the type of climate is one of the main determining factors when deciding between one type of bituminous binder and another.

For use on roads, five types of asphalt bitumen can be differentiated according to their penetration. The most commonly used in Spain are those with a penetration of 35/50 and 50/70, which are used to manufacture conventional bituminous mixes. This is mainly due to climatic reasons as the type of climate is one of the main determining factors when deciding between one type of bituminous binder and another.

Repsol's bitumens improved with rubber actively contribute to increase road quality and safety

Repsol uses proprietary technology to develop so-called "green asphalts" in which the base bitumen is mixed with crumb rubber under certain conditions. Asphalt mixtures for road surfaces manufactured using these rubber bitumens have significant technical advantages such as: lower acoustic impact on reducing the noise levels produced by wheeled traffic and greater adherence.

They also contribute to solving the major environmental problem posed by the accumulation of this waste due to the reuse of more than 10,000 tons of end-of-life tires annually. In short, the use of these bitumens achieves more efficient and eco-friendly asphalt mixtures.